The flat packed housing is composed of top frame components, bottom frame components, columns and several interchangeable wall panels. Using modular design concepts and production technology, modularize a house into standard parts and assemble the house on the construction site.

Structure of the flat packed housing

Wall panel system

Wall panel system Outer board:0.42mm Alu-zinc colorful steel plate, HDP coating

Insulation layer: 75/60mm thick hydrophobic basalt wool (environmental protection), density ≥100kg/m³, class A non-combustible.

Inner board :0.42mm Alu-zinc colorful steel plate, PE coating

Top Frame System Main beam: 3.0mm SGC340 galvanized cold-rolled steel profile. Sub-beam: 7pcs Q345B galvanizing steel, spec. C100x40x12x1.5mm, the space between sub-beams is 755mm. Roof panel: 0.5mm thick Alu-zinc colorful steel plate, PE coating, Alu-zinc content ≥40g/㎡; 360-degree lap joint. Insulation layer: 100mm thickness glass wool felt with aluminum foil on one side, density ≥16kg/m³,class A non-combustible. Ceiling plate: 0.42mm thickness Alu-zinc colorful steel plate, V-193 type (hidden nail), PE coating, galvanized zinc content ≥40g/㎡. Industrial socket: inlaid in the short side of the top frame beam explosion-proof box, a general plug. (pre-punching on the explosion-proof box )Bottom Frame System Main beam: 3.5mm SGC340 galvanized cold-rolled steel profile; Sub-beam: 9pcs "π" typed Q345B, spec.:120*2.0, bottom sealing plate: 0.3mm steel . Inner floor: 2.0mm PVC floor, B1 grade non-combustible; Cement fiberboard:19mm,density ≥ 1.5g/cm³, A grade non-combustible.| Model | Spec. | House outer size(mm) | House inner size (mm) | Weight(KG) | |||||

| L | W | Hpacked | HAssembled | L | W | HAssembled | |||

| Type GFlat packed housing | 2435mm standard house | 6055 | 2435 | 660 | 2896 | 5845 | 2225 | 2590 | 2060 |

| 2990mm standard house | 6055 | 2990 | 660 | 2896 | 5845 | 2780 | 2590 | 2145 | |

| 2435mm corridor house | 5995 | 2435 | 380 | 2896 | 5785 | 2225 | 2590 | 1960 | |

| 1930mm corridor house | 6055 | 1930 | 380 | 2896 | 5785 | 1720 | 2590 | 1835 | |

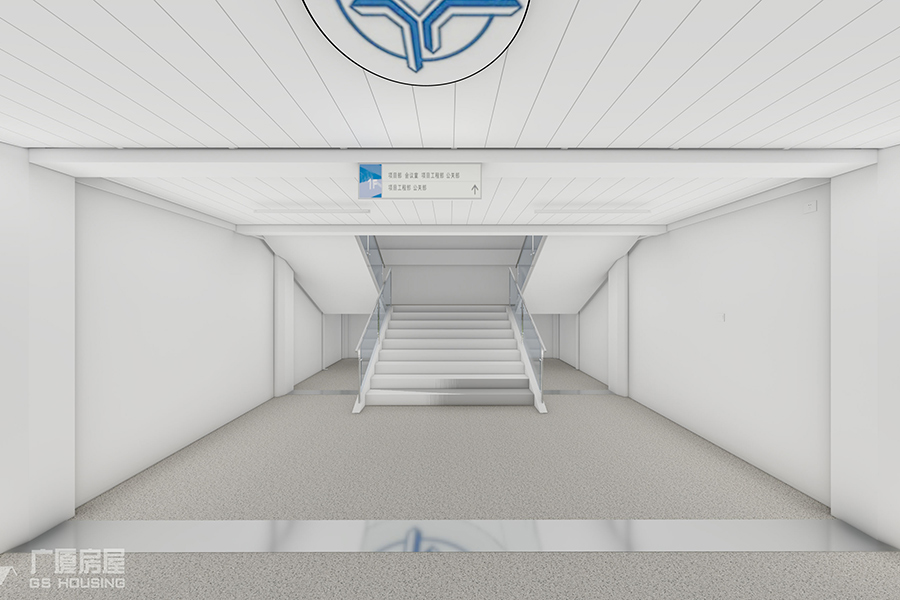

Different function of the flat packed housing

Brife of GS housing group

GS Housing group was established in 2001 withintegrating prefabricated building design, production, sales and construction. GS housing group owns Beijing (Tianjin production base), Jiangsu (Changshu production base),Guangdong(Foshan production base), Sichuan (Ziyang production base), Liaozhong (Shenyang production base), International and Supply Chain Companines. GS housing group is committed to the R&D and production of the prefabricated buildings: flat packed container houses, prefab KZ house, prefeb K&T house, steel structure, which are widely used in various scenarios, such as engineering camps, military camps,temporary municipal houses,tourism and vacation, commercial houses, education houses, and resettlement houses in disaster areas...More Info

Installation of GS Housing Group

Xiamen GS Housing Construction Labor Service Co., Ltd. is a professional installation engineering company under GS Housing Group. which mainly engaged in the installation, dismantling, repair and maintenance of prefabricated K & KZ & T house and container houses, there are seven installation service centers in East China, South China, West China, North China, Central China, Northeast China and International, with more than 560 professional installation workers, and we has successfully delivered more than 3000 engineering projects to customers.

Xiamen GS Housing Construction Labor Service Co., Ltd. is a professional installation engineering company under GS Housing Group. which mainly engaged in the installation, dismantling, repair and maintenance of prefabricated K & KZ & T house and container houses, there are seven installation service centers in East China, South China, West China, North China, Central China, Northeast China and International, with more than 560 professional installation workers, and we has successfully delivered more than 3000 engineering projects to customers. Corner column system

Corner column system The columns are connected with top & bottom frame with Hexagon head bolts(strength: 8.8) The insulation block should be filled in after installed columns. Insulating tapes among the junctions of the structures and the wall panels should be added to prevent the effect of cold and heat bridges and improve the performance of heat preservation and energy saving.

Corner post system Material: 3.0mm SGC440 galvanized cold rolled steel profile columns QTY:four can be interchanged.

Corner post system Material: 3.0mm SGC440 galvanized cold rolled steel profile columns QTY:four can be interchanged. Painting Powder electrostatic spraying, lacquer≥100μm

Painting Powder electrostatic spraying, lacquer≥100μm

Supporting facilities

Installation video of the flat packed housing